Aluminium is a popular material for signage across many industries and applications due to its durability, lightweight nature, and cost-effectiveness. Beyond the surface appeal of these features, the process of aluminium extrusion extends its versatility and potential applications. In this article, we explore the intrinsic qualities of aluminium, the benefits of the extrusion process, and why it has become a staple material in the signage industry.

1. Durable Yet Versatile

Aluminium is renowned for its durability and resilience to harsh weather conditions. Its inherent resistance to corrosion, thanks to a self-forming oxide layer, is further enhanced by coatings like powder coat, wet spray, or anodising, making it an excellent foundation for enduring sign systems.

These attributes make it an ideal material for signage, ensuring longevity without compromising quality. Its lightweight nature facilitates ease of handling and transportation, allowing for the flexibility needed in signage that may require frequent movement or relocation. Moreover, the versatility of aluminum enables it to be cut, shaped, and printed in various ways, providing businesses with a wide array of design options.

2. Cost-Effectiveness of Aluminum Extrusion

The aluminum extrusion process enhances the advantages of this material, particularly in terms of cost-effectiveness. Mass production becomes economically viable as the price per piece decreases significantly compared to other manufacturing methods. This makes aluminum extrusion an attractive choice for producing a diverse range of signs with a cost-efficient approach.

3. Design Freedom and Strength-to-Weight Ratio

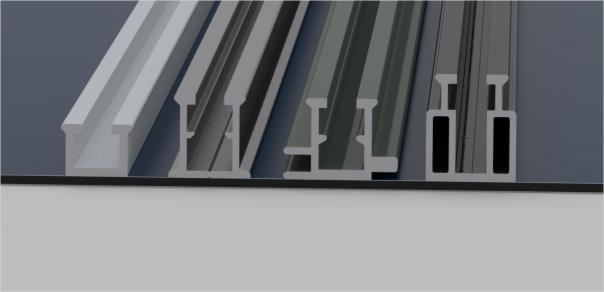

One of the notable benefits of aluminum extrusion lies in the design freedom it offers. Thanks to aluminum’s softer and more malleable nature compared to steel, it allows for effortless manipulation. Cutting, drilling, bending, and forming aluminum requires considerably less effort, providing designers with much greater ease of conversion. The adaptability extends further with the ability to achieve intricate shapes through die alterations, offering boundless possibilities for innovative products with distinctive forms and functionalities.

Moreover, the extrusion process yields a high strength-to-weight ratio, positioning aluminum as an ideal material for creating lightweight designs without compromising strength. This characteristic not only contributes to the cost-efficient transport of materials but also ensures easy handling both onsite and in workshops.

4. Reduced Waste and Sustainability

Aluminium extrusion is a sustainable manufacturing process with a reduced environmental impact. The recyclability of aluminum is key, demanding notably less energy for recycling than extracting from raw bauxite. Approximately 75% of all aluminum ever produced remains in use today. By crafting new aluminum billets from recycled scrap and employing renewable energy sources, a substantial reduction in CO2 footprint can be achieved.

The process generates less waste material compared to alternative methods, contributing to a more eco-friendly production cycle. The ability to reuse extrusions further minimises scrap material, aligning with the growing emphasis on sustainable manufacturing practices.

5. Diverse Applications

Aluminum’s adaptability is evident across various applications, from elevating brand visibility in business premises with post & panel installations to guiding drivers in car parks with regulatory road signs.

In healthcare settings like NHS hospitals, aluminum facilitates clear wayfinding. At the same time, on highways and transport routes, its fully regulated road signs and passively safe signposts ensure safe traffic flow.

From heritage sites blending seamlessly with historical surroundings to educational environments enhanced by informative signage, aluminum’s strength-to-weight ratio and design freedom prove invaluable.

Navigating travellers through transportation hubs, capturing attention in retail spaces, and creating vibrant atmospheres in sports and entertainment venues are all made possible with aluminum’s reliability and flexibility. Moreover, in construction sites, aluminum plays a crucial role in safety and communication, providing temporary traffic and pedestrian sign supplies.

Display extrusions, with their ability to be finished in various coatings, including powder coat, anodising, wet spray, and special effect wood grain and textures, offer endless possibilities when designing various sign and display systems.

Partnering for a Successful Signage Project

Choosing the right supplier for your aluminum signposts, channels, and extrusions is crucial for the success of your signage projects. Consider the following key factors when evaluating potential suppliers: industry experience, efficiency and speed, flexibility and customisation, and reliability and stock availability. A reliable supplier with substantial experience, fast and streamlined services, a wide array of products, and large stock holdings ensures a consistent flow of goods to customers' doors, leading to successful outcomes.